Industrial odour emissions represent one of the most challenging environmental compliance issues facing modern industry. With global odour control system markets projected to reach $2.1 billion by 2035 at a compound annual growth rate of 4.5%, businesses are increasingly investing in sophisticated odour management technologies that deliver both regulatory compliance and community acceptance. This comprehensive exploration examines the latest innovations in industrial odour control, from molecular neutralization technologies to AI-powered monitoring systems, providing essential insights for industry professionals navigating the complex landscape of environmental air quality management.

The Growing Imperative for Industrial Odour Control

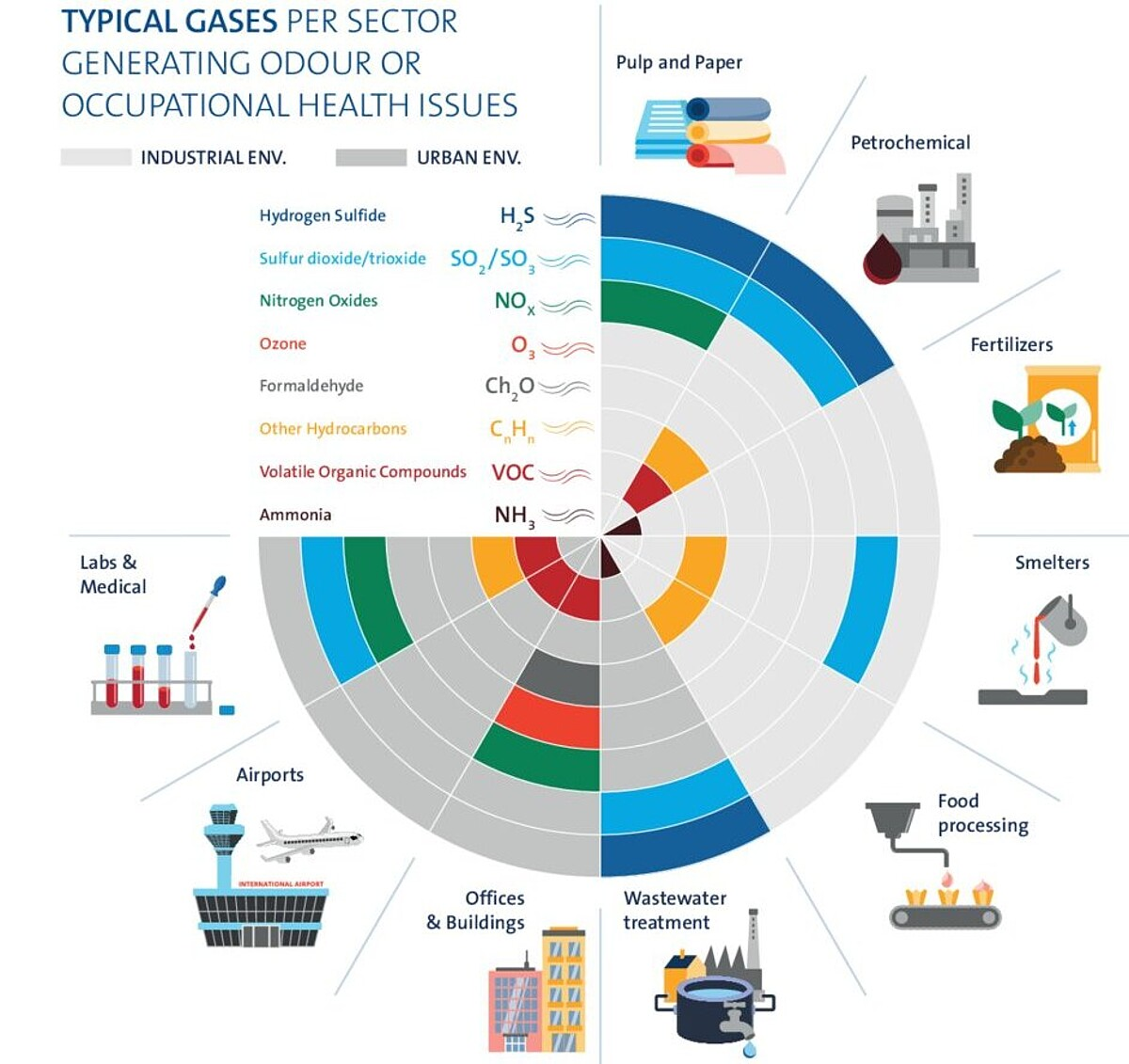

Industrial odour pollution has evolved from a nuisance issue to a critical environmental and public health concern. Modern industrial operations across sectors including wastewater treatment, food processing, chemical manufacturing, and waste management generate complex odour compounds that can travel significant distances from their sources. These emissions, primarily consisting of volatile organic compounds (VOCs), hydrogen sulfide (H₂S), ammonia (NH₃), and various sulfur compounds, pose immediate health risks while contributing to broader air quality degradation.+2

The regulatory landscape has responded with increasingly stringent standards. In industrial parks studied across various jurisdictions, VOC emissions contribute significantly to ground-level ozone formation and photochemical smog, with research indicating that 68% of industry experts believe breakthrough sustainable technologies will dominate the odour management sector by 2025. This regulatory pressure, combined with growing community awareness and corporate sustainability commitments, has created an urgent need for advanced odour control solutions.

Contemporary odour challenges extend beyond simple emission reduction. Industries must now demonstrate molecular-level neutralization rather than masking, implement continuous monitoring systems, and provide transparent community reporting. The complexity of modern odour profiles, often containing multiple compound families including aldehydes, amines, sulfides, and lactones, demands sophisticated technological responses that can address diverse chemical signatures simultaneously.+2

Molecular Neutralization: The Science Behind Permanent Odour Elimination

The fundamental distinction between odour masking and molecular neutralization represents the cornerstone of effective modern odour control. Traditional approaches relied on fragrance masking, where stronger scents temporarily overwhelmed unwanted odours without addressing the underlying chemical compounds. Advanced molecular neutralization technologies operate through entirely different mechanisms, targeting odorous molecules directly to create permanent chemical transformation.

Molecular neutralization works through several sophisticated mechanisms. Encapsulation processes chemically bind with malodorous molecules, creating new molecular structures that are either odourless or non-volatile. Quaternary-ammonium surfactants specifically target mercaptan thiol rings, converting compounds like ethyl mercaptan into odourless ethyl sulphonate through precise chemical reactions[web:source]. Oxidation processes utilizing encapsulated potassium permanganate micro-crystals can neutralize hydrogen sulfide to elemental sulfate in under 0.8 seconds contact time, demonstrating the rapid kinetics possible with properly engineered systems[web:source].+1

The effectiveness of molecular neutralization extends to complex odour mixtures containing multiple compound families. Research demonstrates that properly formulated neutralization systems can achieve over 95% odour removal efficiency across diverse industrial applications. These systems target specific molecular structures including aldehydes, amines, sulfides, lactones, and various VOC families, providing broad-spectrum neutralization capabilities that address the full complexity of industrial odour profiles.+2

Modern molecular neutralization formulations incorporate carefully selected essential oil blends derived from plant, flower, and tree extracts. These natural compounds undergo volatilization into dry vapor form, enabling efficient distribution and molecular pairing with target odour compounds. The process eliminates pungent smells by breaking down foul-smelling molecules at their source, creating permanent odour elimination rather than temporary suppression.+1

Biofilter Technology: Harnessing Natural Processes for Industrial Applications

Biofiltration represents one of the most sustainable and cost-effective approaches to industrial odour control, utilizing naturally occurring microorganisms to oxidize odour compounds into harmless byproducts including carbon dioxide, water, biomass, and inorganic salts. This biological approach provides environmental compatibility while delivering consistent removal efficiencies exceeding 90% for complex odour mixtures.+2

Biofilter systems operate through sophisticated biological processes that mirror natural soil ecosystems. Odorous air streams pass through porous filter media containing established microbial communities that metabolize volatile compounds through aerobic oxidation. The filter media provides essential contact surface area where microorganisms establish biofilms, creating optimal conditions for biological treatment. Key operational parameters include moisture content, pH control, nutrient availability, and temperature management, all of which must be carefully maintained to ensure healthy microbial activity.

Modern biofilter designs incorporate advanced media formulations that extend operational life while improving treatment efficiency. Engineered inorganic media with 20-year design life provides superior performance benefits including reduced maintenance intervals, permanent non-degrading characteristics, high available surface area, and predictable performance across varying inlet conditions. These media innovations enable lower empty bed residence times (EBRT), reducing overall system footprints while maintaining high removal efficiencies.

Biotrickling filters represent an advanced biofilter variant particularly effective for hydrogen sulfide treatment. These systems utilize continuously recirculated liquid phases to maintain optimal pH and nutrient conditions while achieving greater than 99% H₂S removal efficiency. The recirculation design responds exceptionally well to variations in odour inlet concentrations, providing operational flexibility essential for industrial applications with fluctuating emission profiles.+1

Research demonstrates that biofilter systems require approximately six weeks for initial microbial acclimation, during which specialized bacterial populations establish stable treatment communities. However, bio-available micronutrient packages containing copper, manganese, and zinc can accelerate indigenous Thiobacillus colonization, reducing start-up times from six weeks to just 10 days[web:source]. This acceleration significantly improves project implementation timelines while ensuring consistent treatment performance.

Advanced Chemical and Physical Treatment Systems

Chemical and physical odour treatment systems provide essential solutions for high-intensity industrial applications where biological treatment may be insufficient or impractical. These systems employ sophisticated engineering principles to achieve rapid, reliable odour destruction through thermal oxidation, catalytic processes, and advanced scrubbing technologies.+1

Regenerative Thermal Oxidizers (RTOs) represent the most widely accepted technology for VOC and odour destruction in industrial applications. These systems achieve heat recovery efficiencies approaching 97% through ceramic heat storage media, making them extremely energy-efficient for continuous operation. RTOs operate by raising vent gas temperatures to approximately 1,400°F within reaction chambers where hydrocarbons undergo complete oxidation to carbon dioxide and water vapor. The high destruction efficiency and fuel recovery characteristics make RTOs ideal for applications with low VOC concentrations but high annual operating hours.+1

Catalytic oxidation systems offer enhanced efficiency through lower operating temperatures. By incorporating catalytic materials into combustion chambers, these systems achieve complete VOC destruction at temperatures significantly lower than thermal oxidation alone. Metal oxide catalysts enable low-temperature odour destruction while providing improved energy efficiency and decreased secondary emissions. Modern catalytic systems integrate AI-powered chemical dosing control based on real-time pH and oxidation-reduction potential monitoring, optimizing reagent consumption while maximizing destruction efficiency.+2

Chemical scrubbing systems provide targeted treatment for specific compound families through carefully engineered liquid-gas contact processes. Advanced scrubber designs incorporate multi-stage absorption and ionization systems combining activated carbon with electrostatic precipitation for superior air purification performance. These hybrid systems prove particularly effective in chemical and petrochemical sectors where complex odour mixtures require specialized treatment approaches.

Cryocondensation technology represents an innovative approach for VOC emission control that offers unique advantages for certain industrial applications. These systems use controlled cooling to condense volatile organic compounds from gas streams, enabling recovery and reuse of valuable materials while achieving emission control. CIRRUS® cryogenic condensation systems provide safe, cost-effective, and environmentally sound operation with proven performance across terminals, oil and gas complexes, and chemical hubs worldwide.

Artificial Intelligence and Smart Monitoring Systems

The integration of artificial intelligence and IoT connectivity is revolutionizing industrial odour monitoring and control, enabling real-time detection, predictive analytics, and automated response systems that significantly enhance operational efficiency and regulatory compliance.+2

Smart odour monitoring systems utilize sophisticated sensor arrays and machine learning algorithms to detect and identify complex odour patterns in real-time. Electronic nose (e-nose) technologies simulate human olfactory perception through advanced sensor arrays that generate unique digital fingerprints for different odour compounds. These systems provide continuous monitoring capabilities with ppb-level accuracy across multiple sensing modules, enabling early detection and rapid response to emission events.+1

AI-powered monitoring platforms deliver unprecedented analytical capabilities through comprehensive data integration and predictive modeling. Modern systems like the Scentinal platform can accommodate up to 20 sensing modules providing high-accuracy detection of both odorous and scentless gases including hydrogen sulfide, ammonia, volatile organic compounds, mercaptans, and various sulfur compounds. The integration of meteorological monitoring enables correlation between environmental conditions and odour dispersion patterns, supporting more effective emission control strategies.+1

Machine learning algorithms enable sophisticated pattern recognition and predictive maintenance capabilities. These systems analyze historical emission data to identify recurring odour events associated with specific operational conditions, weather patterns, or equipment performance variations. Predictive analytics can forecast potential odour incidents before they occur, enabling proactive intervention and prevention strategies that minimize community impact and regulatory violations.+2

Real-time alert systems provide immediate notification capabilities with data updates every 10 seconds and automated activation of remediation systems when threshold concentrations are exceeded. Advanced platforms integrate animated visualization of pollution plumes with precise source localization through triangulation techniques, providing comprehensive understanding of impact areas and emission origins. This real-time intelligence enables rapid response while supporting transparent community communication and regulatory reporting requirements.

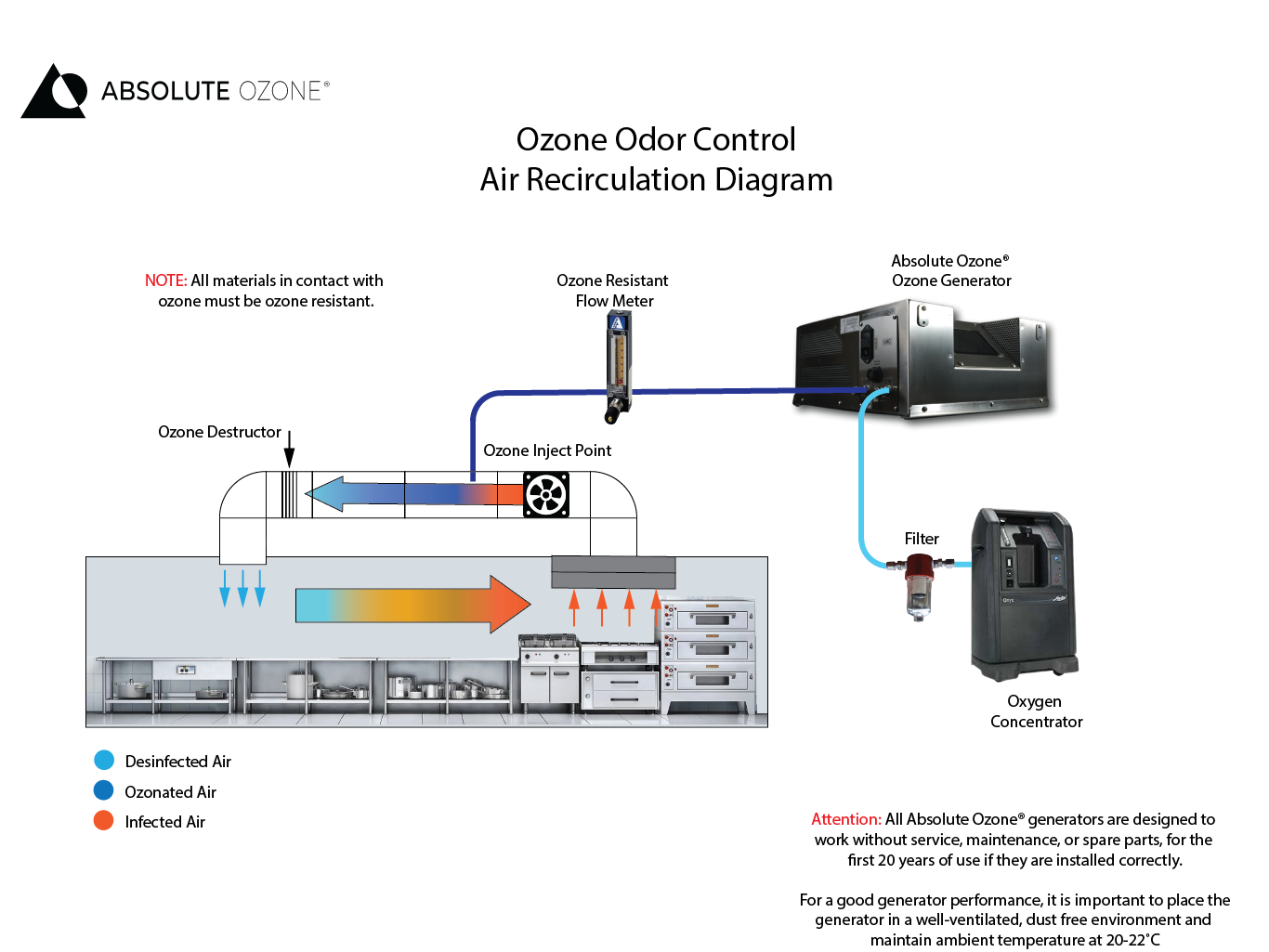

Engineering Delivery Systems for Maximum Effectiveness

The effectiveness of odour control technologies depends critically on properly engineered delivery systems that ensure optimal contact between treatment agents and target compounds while maintaining efficient distribution throughout treatment zones[web:source].

Droplet size optimization represents a fundamental engineering parameter in liquid-based odour control applications. Research demonstrates that low-pressure air-atomizing nozzles operating at 200-400 kPa produce optimal 35-55 μm volume median diameter (VMD) droplets[web:source]. Droplets smaller than 30 μm tend to drift off-site before achieving treatment contact, while droplets larger than 80 μm experience premature fallout before completing chemical reactions[web:source]. This precise droplet size control ensures maximum treatment efficiency while minimizing chemical consumption and environmental impact.

Automated wind-triggered dosing systems integrate real-time meteorological monitoring with programmable logic controllers (PLCs) to optimize treatment application based on environmental conditions. When wind direction shifts toward sensitive receptors, automated systems can ramp dosing rates by 1.8× within 90 seconds, providing immediate response to changing dispersion patterns[web:source]. This automation ensures consistent protection while optimizing chemical usage and operational costs.

Specialized delivery applications address unique industrial challenges through targeted engineering solutions. Leachate-tank headspace fogging systems operate at 0.3 L m⁻³ min⁻¹ using intrinsically safe ATEX-rated pumps, preventing "puff" emissions that occur when barometric pressure drops exceed 3 hPa in 30-minute periods[web:source]. These specialized systems demonstrate the sophisticated engineering required for effective odour control in challenging industrial environments.

Integration of odour control systems into existing process water streams provides 24/7 coverage through embedded treatment approaches. Anoxic zone dosing with 3-5 ppm non-oxidizing biocides upstream of primary clarifiers effectively controls sulfate-reducing bacteria populations without harming beneficial nitrifying organisms[web:source]. Similarly, addition of 0.2% v/v terpene-based odour control agents to polymer feed tanks suppresses aroma release during high-shear mixing operations while maintaining process effectiveness[web:source].

Regulatory Compliance and Documentation Strategies

Modern odour control implementation requires comprehensive documentation and data management strategies that support regulatory compliance while enabling continuous performance optimization and community transparency[web:source].

Chain-of-custody laboratory reports documenting pre- and post-treatment VOC concentrations (μg m⁻³) provide essential evidence of treatment effectiveness and regulatory compliance[web:source]. These analytical results, combined with meteorological logs correlating dosing events with wind speed, direction, and atmospheric stability class, create comprehensive documentation packages that demonstrate due diligence and treatment effectiveness[web:source].

Community engagement strategies increasingly incorporate digital technology platforms that enable transparent communication and real-time feedback collection. Modern odour-tracking applications allow residents to log episodes in real-time, generating time-stamped CSV files that provide valuable correlation data for system optimization[web:source]. When dosing data shows no chemical application during reported odour spikes, operators can refine protocols and identify alternative sources rather than facing regulatory penalties[web:source].

ESG reporting and carbon credit opportunities represent emerging value propositions for advanced odour control implementation. Improved odour management enhances landfill gas capture efficiency, unlocking carbon credits while boosting environmental, social, and governance (ESG) performance scores[web:source]. This connection between odour control and broader sustainability metrics creates additional business value while supporting corporate responsibility objectives.

Regulatory frameworks continue evolving toward more stringent emission standards and comprehensive monitoring requirements. The Technical Framework for Assessment and Management of Odour from Stationary Sources provides guidance for systematic odour evaluation and management planning. Successful compliance strategies integrate proactive monitoring, documented response procedures, and community engagement protocols that demonstrate commitment to environmental stewardship while maintaining operational efficiency.

Industry-Specific Applications and Case Studies

Different industrial sectors present unique odour control challenges requiring specialized technology selection and implementation strategies based on specific emission profiles, operational requirements, and regulatory frameworks.+1

Wastewater treatment facilities represent the largest consumer segment for odour control technologies, with municipalities and industrial operators deploying advanced biofilter and chemical scrubbing systems to address hydrogen sulfide, ammonia, and organic compound emissions. Modern wastewater treatment odour control can reduce community complaints by as much as 80%, significantly improving community acceptance and regulatory compliance. Integration of thermal oxidation and biofiltration systems for methane and VOC control in landfill gas management applications demonstrates the multi-technology approaches required for comprehensive emission control.

Food and beverage processing operations increasingly implement specialized odour control systems addressing organic decomposition odours from meat processing, dairy operations, and fermentation processes. Carbon-based odour control systems including biotrickling filters achieve exceptional ammonia and protein decomposition odour removal, meeting heightened sanitation demands while maintaining consumer confidence. Smart odour monitoring and air purification systems with AI-driven analytics provide automated control that ensures consistent performance across varying production schedules and seasonal variations.

Chemical and petrochemical industries require high-efficiency systems capable of handling complex VOC mixtures and high-concentration emission streams. Advanced oxidation processes combined with catalytic destruction systems provide the robust treatment capabilities necessary for regulatory compliance in these demanding applications. Integration of regenerative thermal oxidation with heat recovery enables cost-effective operation while achieving the high destruction efficiencies required for these applications.+2

Agricultural and livestock operations present unique challenges requiring specialized formulations and delivery systems adapted to outdoor environments and biological processes. Biofilter systems designed for large infrastructure applications provide cost-effective treatment for complex odour profiles while maintaining compatibility with agricultural operations. Modern systems integrate predictive odour dispersion modeling with real-time meteorological monitoring to optimize treatment timing and minimize community impact during sensitive weather conditions.+1

Future Innovations and Emerging Technologies

The future of industrial odour control is being shaped by convergent innovations in nanotechnology, artificial intelligence, biotechnology, and sustainable chemistry that promise enhanced effectiveness, reduced environmental impact, and improved economic performance.

Nanotechnology-based adsorbents represent a significant advancement in physical odour control systems, offering enhanced surface area and selective adsorption capabilities that improve treatment efficiency while reducing system footprint requirements. AI-driven airflow optimization combined with hybrid UV-carbon filtration systems enhances performance, durability, and adaptability across varying operating conditions. These technological convergences address traditional limitations of physical odour control systems while maintaining their inherent advantages.

Biotechnology innovations focus on enhanced microbial systems with improved stability, broader compound specificity, and reduced acclimation periods. Enzyme-based odour neutralization systems provide sustainable alternatives to chemical treatment while achieving comparable effectiveness across diverse odour compound families. Bio-compatible scrubbing solutions integrated with AI-assisted real-time tracking enable precise control while minimizing environmental impact.

Sustainable chemistry developments emphasize biodegradable, non-toxic formulations derived from renewable resources while maintaining high performance standards. The market projection that sustainable odour management technologies will comprise over 50% of the market by 2025 reflects growing environmental awareness and regulatory pressure for eco-friendly solutions. These developments align with broader corporate sustainability commitments while addressing community concerns about chemical treatment approaches.

Digital integration and IoT connectivity will enable comprehensive ecosystem monitoring with real-time sensor networks providing continuous air quality assessment across extended facility boundaries. Predictive analytics will anticipate equipment maintenance needs, optimize chemical dosing, and forecast emission events before they impact surrounding communities. This proactive approach transforms odour control from reactive compliance to predictive environmental stewardship.+1

Conclusion: Engineering a Sustainable Future for Industrial Odour Control

The evolution of industrial odour control reflects broader trends toward environmental sustainability, technological sophistication, and community engagement that define modern industrial environmental management. As regulations become more stringent and community expectations continue rising, successful odour control strategies must integrate molecular-level treatment effectiveness, real-time monitoring capabilities, and transparent performance documentation.+2

The projected growth of the global odour control market to $2.1 billion by 2035 demonstrates the significant economic opportunity associated with advanced environmental technologies. However, success requires moving beyond simple compliance toward comprehensive environmental stewardship that delivers lasting results through molecular neutralization, sustainable treatment approaches, and intelligent monitoring systems.+3

Modern odour control implementation demands integrated approaches that combine proven technologies like biofilters and thermal oxidation with emerging innovations including AI-powered monitoring, nanotechnology-enhanced adsorbents, and sustainable chemistry formulations. The 68% of industry experts who predict sustainable technology dominance by 2025 reflect the fundamental shift toward environmental responsibility that characterizes leading industrial operations.+2

The future belongs to organizations that embrace comprehensive odour management strategies integrating molecular neutralization science, intelligent monitoring systems, and community engagement protocols that demonstrate genuine commitment to environmental stewardship. This transformation from reactive compliance to proactive environmental leadership creates competitive advantages while supporting the broader transition toward sustainable industrial practices that benefit both business operations and community well-being.+2

Through careful selection and implementation of advanced odour control technologies, industrial operations can achieve permanent odour elimination, regulatory compliance, and community acceptance while supporting broader sustainability objectives that define successful 21st-century industrial environmental management.

No comments:

Post a Comment