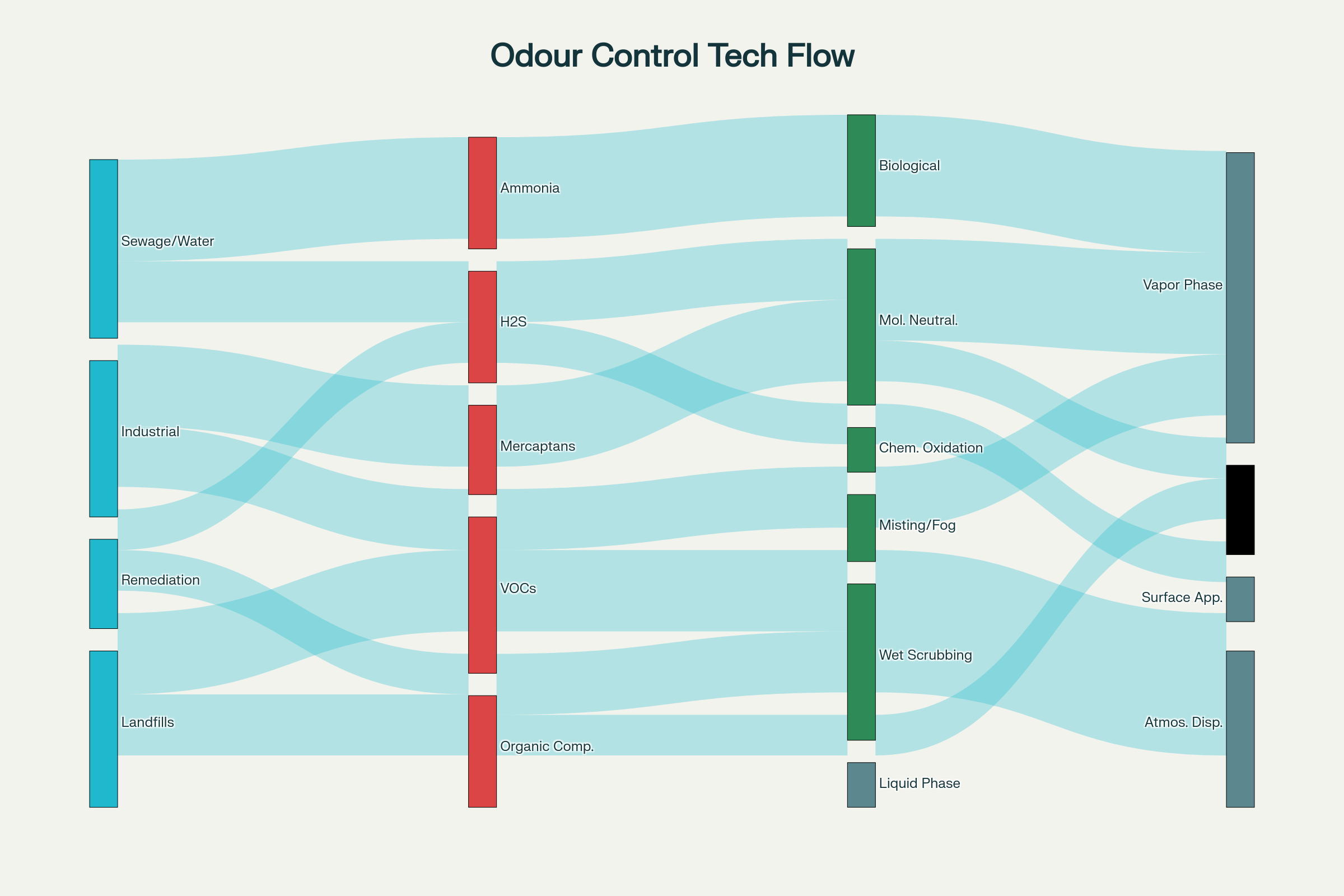

Environmental odour control has become increasingly critical as urban development expands closer to industrial facilities, waste management sites, and remediation projects. From sewage treatment plants to landfills, industrial operations to contaminated site cleanup, effective odour management protects public health, ensures regulatory compliance, and maintains positive community relations.+2

Modern odour control technology has evolved far beyond simple masking agents. Today's solutions target odours at the molecular level, neutralizing compounds rather than covering them up. This comprehensive guide explores the latest approaches to odour control across four key sectors: sewage and wastewater treatment, landfills, industrial applications, and environmental remediation.

Understanding the Science of Odour Formation

Odours are caused by volatile organic compounds (VOCs) and gases such as hydrogen sulfide (H₂S), ammonia, mercaptans, and various organic compounds. These molecules become airborne and trigger our olfactory receptors, creating unpleasant sensations that can indicate serious underlying environmental issues.+2

Hydrogen sulfide is particularly problematic in wastewater applications, producing the characteristic "rotten egg" smell while also being highly toxic and corrosive. At concentrations as low as 0.0047 ppm, H₂S becomes detectable, yet it remains dangerous at much higher levels, potentially causing respiratory issues, nervous system effects, and even death.+2

The formation of these odorous compounds typically occurs under anaerobic conditions where sulfate-reducing bacteria thrive. Understanding this process is crucial for developing effective control strategies that address the root cause rather than just the symptoms.+1

Sewage and Wastewater Treatment: Controlling H₂S at the Source

Wastewater treatment facilities face unique odour challenges due to the complex chemistry of sewage and the extended retention times that allow anaerobic conditions to develop. The primary culprits include hydrogen sulfide, ammonia, and various organic compounds that form during the decomposition process.+1

Liquid Phase Control Strategies

Molecular neutralization technology represents the most advanced approach to wastewater odour control. This method works by breaking down odorous compounds at the molecular level, converting them into harmless byproducts like water and CO₂. Unlike traditional masking agents, molecular neutralization eliminates odours permanently without introducing fragrances or temporary fixes.+1

Chemical oxidation using hydrogen peroxide, ozone, or chlorine dioxide provides effective H₂S control in force mains and wet wells. These oxidants target sulfides and related compounds, preventing odour formation before gases can escape to the atmosphere. The key is dosing at strategic points closest to the source for maximum efficiency.+1

pH adjustment using magnesium hydroxide (such as ACTI-Mag™) offers a safe, cost-effective approach to odour control. By raising wastewater pH to 8.5-9.0, very little H₂S is released as gas, effectively controlling odours while providing additional benefits for downstream treatment processes.

Vapor Phase Treatment

When liquid phase control isn't sufficient, vapor phase treatment captures and treats foul air before atmospheric release. Wet scrubbing systems pass contaminated air through packed towers with alkaline solutions, effectively removing H₂S from the gas stream. These systems work well where hydrogen sulfide dominates and airflows are predictable.+1

Biological filtration uses microorganisms to convert H₂S and ammonia into harmless products. Biofilters handle mixed odours effectively and offer low operating costs once established, making them ideal for wastewater treatment plants with diverse odour profiles.+1

Activated carbon adsorption provides compact, effective treatment for odour molecules, particularly useful for handling short, sharp odour peaks. Sydney Water's innovations in activated carbon testing have resulted in 56% longer media service life and over $1 million annual savings.+2

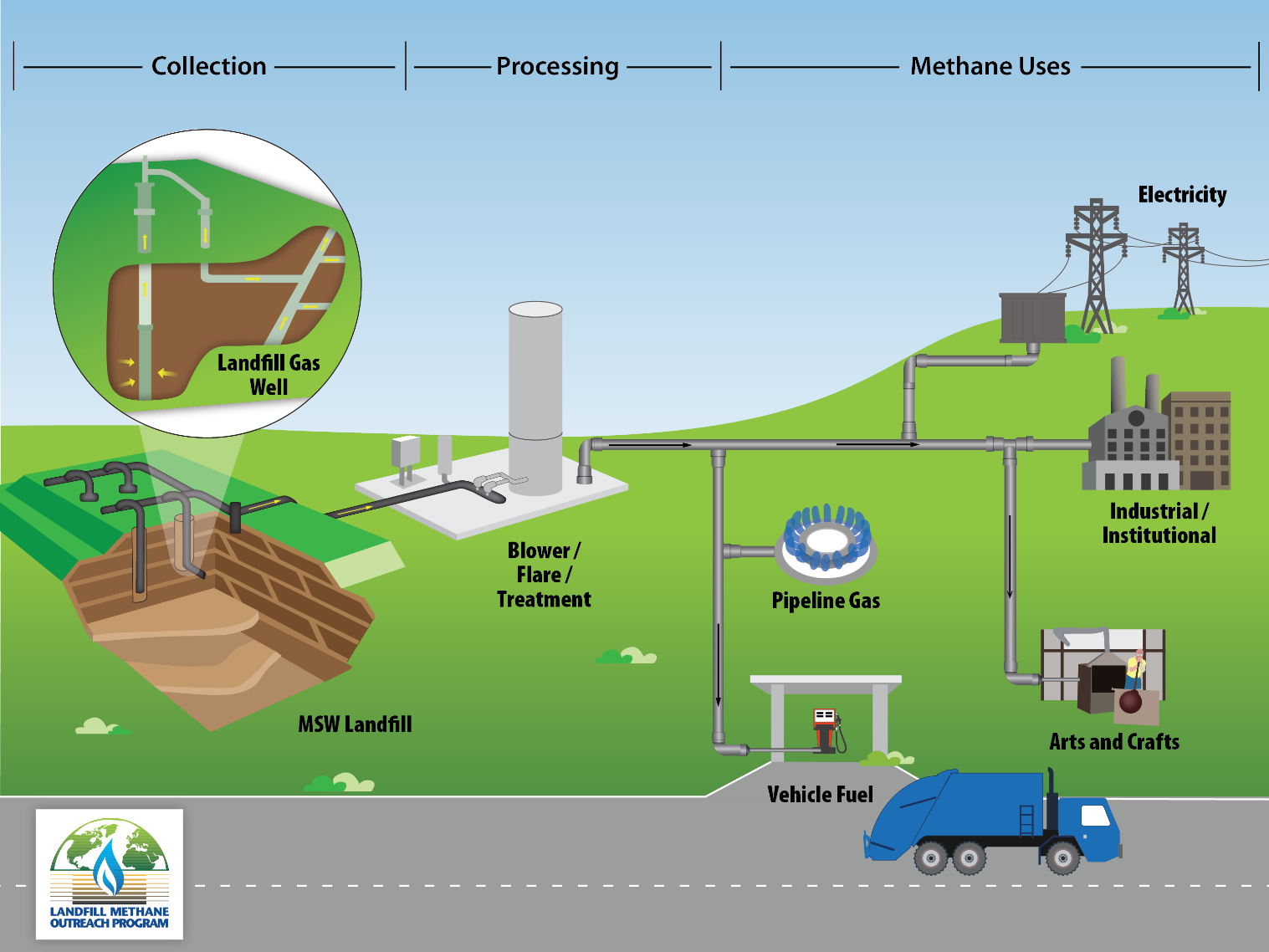

Landfill Operations: Managing Large-Scale Diffuse Emissions

Landfills present unique odour control challenges due to their large size, diffuse emission sources, and varying waste compositions. Modern landfill odour management requires sophisticated approaches that combine real-time monitoring, predictive modeling, and targeted treatment strategies.+2

Surface Treatment Technologies

Odor-Shell® technology represents an innovative solution for landfill surface treatment. This patent-pending clay-based system infused with neutralizers can be spray-applied as a slurry that dries like stucco, adhering to any surface and remaining effective in wet or cured forms. The system works in any weather condition and can provide odour control for up to a year with durability enhancers.

Atmospheric misting and fogging systems create osmogenic barriers that wrap and neutralize malodorous molecules before they disperse into surrounding communities. These systems use high-pressure misting to distribute neutralizing solutions across large areas, making them ideal for treating working faces, roads, and leachate containment areas.+2

Advanced Monitoring and Predictive Management

Modern landfills increasingly rely on environmental intelligence software such as Envirosuite's Omnis platform to proactively manage odour risks. These systems combine real-time odour monitoring, weather forecasting, and trajectory modeling to:+2

Predict odour impact up to 72 hours in advance

Identify emission sources through reverse trajectory modeling

Optimize work scheduling during high-risk weather conditions

Provide transparent community engagement through web portals+1

This proactive approach enables landfill operators to schedule the most odorous activities during favorable weather conditions while maintaining positive community relations.+1

Mobile Treatment Systems

Mobile vapor systems capable of moving with working faces provide the most effective approach to source control. These systems can get close to odorous compounds as they're generated, neutralizing them before escape to surrounding areas. The proximity to the source significantly impacts efficacy, as odour neutralization depends on direct contact between neutralizer and odour molecules.

Industrial Applications: Customized Solutions for Diverse Processes

Industrial odour control requires tailored approaches that account for specific chemical processes, facility layouts, and regulatory requirements. Manufacturing facilities, chemical plants, food processing operations, and other industrial sites each present unique odour profiles requiring specialized treatment strategies.+2

Process-Integrated Odour Control

Integrated system design considers odour control from the initial facility planning stages. Effective strategies include:

Positioning odour-producing processes close to treatment systems

Facing receiving bays away from sensitive receptors

Using automated door systems and airlocks to contain emissions

Implementing truck wash facilities to prevent odour tracking

Chemical neutralization systems using specialized formulations can be integrated directly into industrial processes. These systems react with odorous compounds to convert them into non-odorous substances, providing real-time treatment as emissions are generated.+1

Advanced Application Methods

Spraying systems and cannons provide flexible odour control for industrial facilities. These systems can be configured as fixed installations or mobile platforms, offering both waterless vapor distribution and water-soluble concentrate atomization depending on specific requirements.+1

Biofilter technology offers environmentally friendly odour treatment for industrial emissions. These systems use microbial activity to break down odorous compounds as contaminated air passes through organic media beds, providing effective treatment without hazardous chemicals.+1

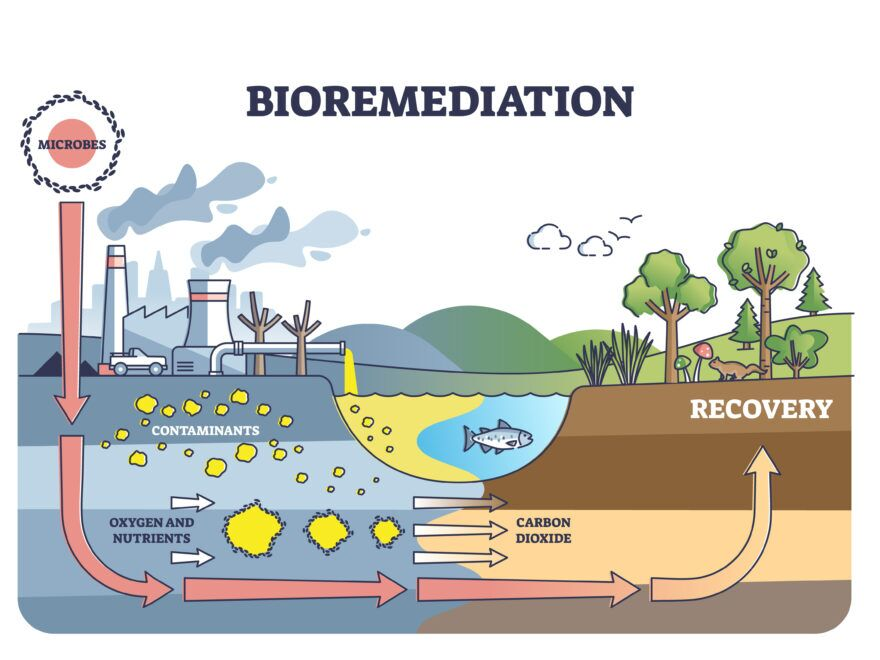

Environmental Remediation: Managing Contaminated Site Odours

Remediation projects often encounter significant odour challenges when disturbing contaminated soils and groundwater. These odours can include petroleum hydrocarbons, industrial solvents, and other chemical compounds that pose risks to workers and nearby communities.+2

Site-Specific Odour Management

Comprehensive odour management plans are essential for remediation projects. Key components include:+1

Pre-characterization of potential odour sources

Selection of appropriate odour control technologies

Implementation of monitoring and verification protocols

Community engagement and complaint response procedures+1

Thermal treatment considerations require special attention, as processes like thermal desorption can generate complex odour profiles. Research has shown that compounds like trimethylamine (TMA) can form during high-temperature treatment of contaminated materials, creating intense "fishy" odours with extremely low detection thresholds.

Treatment Technologies for Remediation

Enclosure systems with odour control provide the most effective approach for remediation sites. Odour control enclosures (OCEs) contain emissions during soil excavation and treatment, with exhaust air treated through scrubbers, biofilters, or activated carbon systems before atmospheric release.

Surface treatment products like hydrocarbon mitigating agents and specialized foams can be applied directly to contaminated materials. These products create barriers that prevent odour release while allowing remediation processes to continue effectively.+1

Deodorizing misting systems at site boundaries provide additional protection for surrounding communities. These systems create treated air barriers that neutralize any odours that escape primary containment systems.

Emerging Technologies and Future Directions

The odour control industry continues to evolve with new technologies and approaches that improve effectiveness while reducing environmental impact. Molecular odour neutralization represents the current state-of-the-art, but ongoing research focuses on:

Enhanced biological treatment systems with improved media and process control

Smart monitoring networks with AI-powered predictive capabilities

Sustainable treatment chemicals derived from natural plant compounds

Integrated treatment approaches combining multiple technologies for optimal performance+2

Best Practices for Implementation

Successful odour control implementation requires careful consideration of site-specific factors, regulatory requirements, and community expectations. Key best practices include:

Comprehensive assessment of odour sources, compounds, and meteorological conditions before selecting treatment technologies. Understanding the specific chemistry and emission patterns enables optimal system design.

Multi-barrier approaches combining prevention, containment, and treatment provide the most reliable odour control. No single technology addresses all situations, so layered strategies ensure consistent performance.+1

Regular monitoring and maintenance keeps systems operating at peak efficiency. This includes performance verification, equipment maintenance, and adaptive management based on changing conditions.+1

Community engagement builds trust and provides early warning of potential issues. Transparent communication and responsive complaint handling maintain social license to operate.+1

Regulatory Compliance and Environmental Benefits

Modern odour control solutions not only address immediate odour concerns but also provide broader environmental benefits. Non-toxic, biodegradable formulations protect ecosystems while ensuring worker and community safety. Many advanced systems achieve over 95% odour removal efficiency while meeting strict environmental regulations.+2

Cost-effective implementation through proper system selection and maintenance provides long-term value. Studies show that proactive odour management reduces complaints, avoids regulatory penalties, and maintains positive community relations – often paying for itself through avoided costs and operational efficiencies.+3

The evolution from simple masking agents to sophisticated molecular neutralization systems represents a fundamental shift in odour control philosophy. By addressing odours at their source and treating them through scientifically proven methods, modern facilities can achieve effective, sustainable odour management across all industry sectors.

For organizations seeking proven odour control solutions, partnering with experienced specialists like Anotec Environmental ensures access to cutting-edge molecular neutralization technology and expert technical support tailored to specific operational requirements. Through proper assessment, system design, and ongoing optimization, effective odour control becomes an achievable goal for any facility or operation.

No comments:

Post a Comment